Centre for Sustainable Engineering

Facilities

On this page:

- Combustion Laboratory

- Computational Modelling Facilities

- Confocal Laser Scanning and Super-resolution Microscopy Lab

- Electrical Characterisation Facilities

- Electrochemistry Facilities

- Hardness Test Machine

- Materials Characterisation Lab

- Materials Engineering in Magnetic Fields (MagMat) Facility

- Mechanical Testing Facilities

- Mechanical Workshop

- Nano Fluids Research Labs

- NanoVision Centre

- Photoelectrochemical Imaging Lab

- Photoelectron Spectroscopy Facility

- Photovoltaic device testing

- Piezoelectric energy harvester tester

- Polymer Processing Facility

- Spectroscopy Facility

- Sustainable Thermal Systems Laboratory

- The Makerspace

- Thermal Analysis Facility

- Thermoelectric Generator Testing Facility

- Thermoelectric Suite

- Undergraduate Teaching Labs

- X-Ray Diffraction Facility

Combustion Laboratory

Research in combustion science concentrates on engine performance testing and emissions. The Internal Combustion Engine laboratory contains five test beds. These include a four cylinder diesel engine with optical access to the combustion chamber and a variable compression ratio Ricardo engine. Current projects include duel fuelling and the development of biodiesels as alternative fuels for compression ignition engines. In addition the school possesses an almost unique, high pressure, steady-state combustion rig for studying the fundamental physics behind the combustion process.

Contact: Prof Xi Jiang

Computational Modelling Facilities

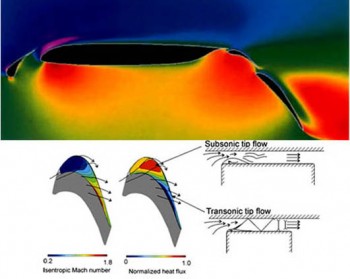

Prediction of flow around : 1- A Multi-Element Wing 2-A Jet Engine Gas Turbine Blade using Computational Aerodynamics.

Researchers of the Centre have prime access to 6 dedicated Lenovo ThinkSystem SD530 compute nodes with Cascade Lake CPUs.

Altogether, the compute nodes are equivalent to an HPC cluster of about 300 CPU cores for running parallel simulations on-demand.

This is In addition to several more Lenovo CPU compute nodes and high-performance GPU cards, such as A100 owned by individual research groups of the Centre.

The Aerospace Group also has access to the National Supercomputer Facilitiy (HECToR), QMUL Computing Cluster and Distributed Advanced Work Station at the School of Engineering and Materials Science.

In addition, our undergraduate students are being taught Computational Methods and use Industry Based Computing packages such as (ABAQUS) for Aerospace Structures and FLUENT for Computational Aerodynamics. These packages are currently being used by Aerospace Industries such as Airbus and BAe systems.

Contact: Prof Sergey Karabasov

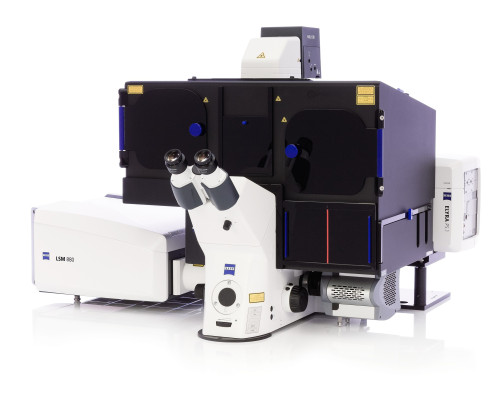

Confocal Laser Scanning and Super-resolution Microscopy Lab

SEMS hosts a confocal microscopy containing two laser scanning confocal microscopes - a Perkin Elmer spinning disc system and a Leica SP2 with multiphoton laser and lifetime imaging system. In addition we will soon be purchasing a new confocal microscope associated with a super-resolution system. The unit enables live cell fluorescence imaging (GFP, calcium imaging etc), 3D reconstruction and morphological measurement, photobleaching assays such as FRAP and FLIP and fluorescence lifetime microscopy(FLIM). The microscopes also interface with sophisticated mechanical loading systems for tissues, individual living cells (micropipette aspiration) and artificial constructs.

Contact: Prof Martin Knight

Electrical Characterisation Facilities

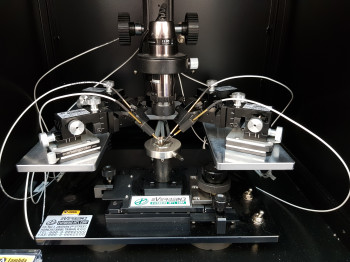

Low noise probe station

A range of electrical characterisation facilities are available for the measurement of electrical conductivity, field-effect mobility and device characteristics. This includes a 4-point probe resistivity measurement system (Osilla) and a shielded low noise probe station. These can be connected to a range of units including a Keithley 2636B SMU, a Keithley 3390 Function Generator, a Keithley 6517B/E electrometer and a GW Instek 8105G LCR meter.

Contact: Dr Oliver Fenwick

Electrochemistry Facilities

Zahner photoelectrochemistry station

We have a wide range of electrochemical and photoelectrochemical facilities for testing of energy materials. These include:

- Xe lamp 400W with solar simulator filter, potentiostat and electrochemical cell: for photocurrent measurements of photoelectrodes in multiple electrolytes, in a three-electrode (half cell) configuration, under 1 sun simulated conditions (with IR filter to avoid overheating of lamp and sample).

- Zahner photoelectrochemistry station: fully integrated photoelectrochemical workstation for high accuracy QE/IPCE measurements. Also with a tuneable LED light source that allows to measure photocurrent response at different wavelengths and possibility of measure electrochemical impedance spectroscopy, too.

- Rotating Disc Electrode (RDE) and potentiostat (with FRA for measuring electrochemical impedance spectroscopy): RDE in three-electrode electrochemical cell configuration with potentiostat to measure the electrocatalytic activity of new materials towards the oxygen evolution reaction (OER) and oxygen reduction reaction (ORR)

- Potentiostat Biologic (+/- 5V -10A) and redox flow battery system: for measuring the performance of electrode materials in full cell configuration for redox flow cell applications.

Contact: Dr Ana Sobrido

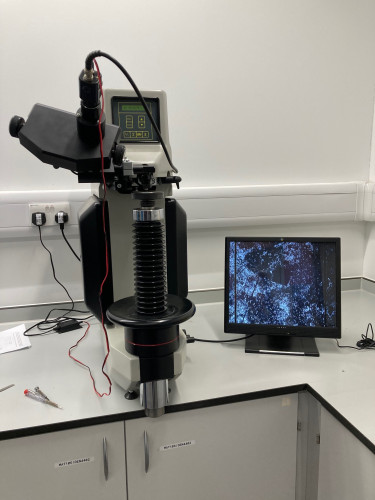

Hardness Test Machine

Hardness Test Hardness tester available in G27

Zwick-Roell Hardness Test Machine. Loads from 3kgf to 150kgf. The indenters available are Rockwell diamond and spherical, Brinell (1.0 andf 2.5mm diameter) and Vicker's diamond. At these load levels mainly used for metals and ceramics. There is an attached camera for recording processes.

Contact: Dr Erica di Federico

Materials Characterisation Lab

We provide a full analysis service in materials science and contains an impressive variety of analytical equipment to cover a broad range of tests and analyses, which are used for structural, thermal and mechanical analysis. The facility offers an analysis service to university-based and external users, both industrial and academic. The lab is located in the Engineering building (Room 232) at the Mile End campus. There are a range of charges for using these facilities.

Contact: Dr Shoghik Hakobyan

Materials Engineering in Magnetic Fields (MagMat) Facility

MagMat is a unique capability in the UK for the synthesis and processing of materials in strong magnetic fields (SMF) known at MagMat. This project provides the initiative for a new era of materials science where magnetic field driven forces are coupled with materials synthesis and processing to produce novel materials. Magneto related phenomena have special relevance to the fields of functional materials and biosciences, where the engineering outcomes are often a result of multifunctional couplings. The use of high magnetic fields in combination with a wide range of processing techniques could lead to new phenomena, materials and manufacturing routes. Our Work is focused on four main research areas of interest where strong magnetic fields can be employed to engineer a wide range of materials - texturing, synthesis, processing and self-assembly.

Contact: Prof Michael Reece

Contact: Dr Salvatore Grasso

Mechanical Testing Facilities

Instron 3340 series materials testing system

The School has a variety of mechanical testing equipment used to determine the mechanical properties of different materials and structures ranging from aircraft components to new implant materials or even biological tissues. These testing machines apply forces in compression, tension or torsion and can be used to find out material properties such as ultimate strength and modulus.

Contact: Dr Erica Di Federico

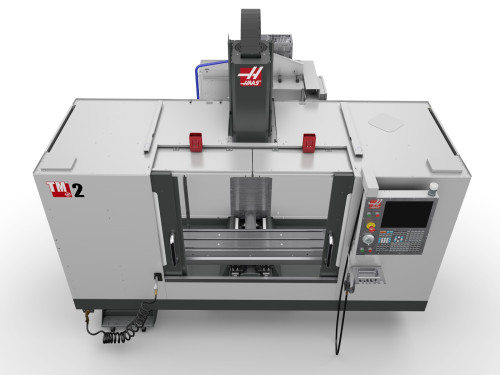

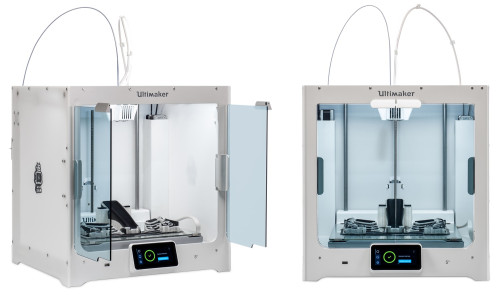

Mechanical Workshop

The School of Engineering and Material Science has a purpose built, fully equipped mechanical workshop where students and academics can come and have their parts manufactured for both research and projects relating to their field of interest. It contains both manual and CAD/CAM controlled milling and turning machines for high-speed production of complex parts in a variety of materials. Also available is a state-of-the-art FDM 3D printer for rapid prototyping in a broad range of thermoplastics. Designs and ideas can be realised by apprentice trained mechanical technicians with years of experience in a variety of engineering backgrounds.

Nano Fluids Research Labs

The School has a rapidly expanding group working on heat transfer from nano-fluids which are liquids containing nano-scale particles that act to alter the fundamental thermo-physical properties of the fluid and so increase heat transfer rates. The specific research includes formulation of nanoparticles and stable nanofluids in a purpose built laboratory. In addition, a new test facility is being constructed to investigate flow and heat transfer behavior of nanofluids in micro-tubes. The research will include mechanistic analysis of micro/nanoscale energy transportation and enhanced heat transfer performance.

NanoVision Centre

The NanoVision Centre is a state-of-the-art microscopy unit which brings together the latest microscope techniques for structural, chemical and mechanical analysis at the nanometer scale (1/1000000 mm). The facility contains an impressive range of electron microscopes, scanning probe microscopes and associated analytical equipment for use in the cutting-edge research being conducted by students and staff.

Contact: Dr Subash Rai

Photoelectrochemical Imaging Lab

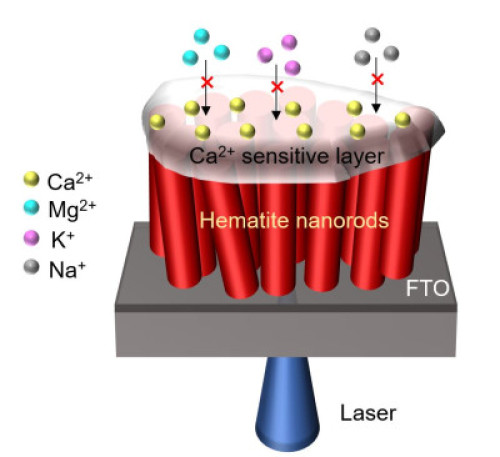

Photoelectrochemical calcium ion sensor based on hematite nanorods

Light-Addressable Potentiometric Sensors (LAPS) and Scanning Photo-induced Impedance Microscopy (SPIM) are imaging techniques based on photocurrent measurements at electrolyte/insulator/silicon (EIS) field-effect structures. They are capable of measuring local changes in the surface potential (LAPS), which can be used to image ion concentrations, and of measuring the local impedance (SPIM).

LAPS and SPIM have great potential as tools for functional electrochemical imaging of the attachment area of cells, providing information such as ion concentration, extracellular potentials and cell impedance. The techniques are particularly attractive for analysing responses of cells with planar polarisation or cell types that separate one compartment from the other as the cell-surface attachment area is not accessible to conventional electrophysiological and electrochemical imaging.

Contact: Prof Steffi Krause

Photoelectron Spectroscopy Facility

ThermoFisher Nexsa X-ray Photoelectron Spectrometer (XPS) System

A ThermoFisher Nexsa X-ray Photoelectron Spectrometer (XPS) System enables a range of photoelectron spectroscopy measurements on a range of materials. It includes facility for:

- X-ray photoelectron spectroscopy (XPS)

- Ultraviolet photoelectron spectroscopy (UPS)

- Reflection electron energy loss spectroscopy (REELS)

- Ion Scattering Spectroscopy (ISS)

Contact: Dr Richard Whiteley

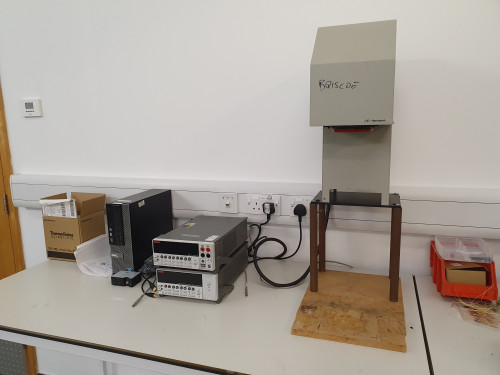

Photovoltaic device testing

Newport AAB solar simulator

Newport AAB solar simulator with AM1.5 full solar illumination for testing of photovoltaic devices. Test facilities include a Keithley 2400 source-measure unit and associated PC and test software.

Contact: Dr Joe Briscoe

Piezoelectric energy harvester tester

Full test facilities for testing output performance of piezoelectric energy harvesters, including:

Permanent magnetic shaker (Brüel & Kjær LDS V406)

Digital oscilloscope (Tektronix TDS2012C)

Low noise current preamplifier (Stanford Research Systems SR 570)

Signal generator and amplifier

Variable resistance box

Contact: Dr Joe Briscoe

Polymer Processing Facility

As the first UK Materials department (1967) and one of the five Science Research Council funded Polymer Research Centres in a Materials Department, we have a long standing history and extensive research expertise in polymer and composites processing. Ranging from melt-processing (single and twin-screw extruders, injection moulding, film blowing, solid state stretching) to solution processing (electrospinning, spin coating), a wide range of polymer processing and composites equipment is available at our lab.

Contact: Dr Han Zhang

Contact: Dr Dimitrios Papageorgiou

Spectroscopy Facility

FTIR equipment for materials analysis.

We have a variety of sophisticated spectrometers which are used to identify specific compounds and investigate composition of materials prepared as either a liquid, solid, film or powder. These devices include:

- Fourier Transform Infrared Spectroscopy (FTIR)

- Raman Spectroscopy

- Near InfraRed Spectroscopy (uv-vis NIR).

Contact: Dr Shoghik Hakobyan

Sustainable Thermal Systems Laboratory

Microchannel rig to measure local condensation and flow boiling heat transfer using inverse method.

The School has an international reputation for research into two-phase flow with heat transfer. In particular, it has five test rigs for investigating various aspects of condensation and flow boiling heat transfer which has direct applications to steam power plant, nuclear power plant, organic Rankine cycle (ORC), refrigerators and air conditioners, heat pumps, solar assisted heat pump based heating systems, advanced thermal management of data centre and electric vehicle batteries and air conditioning systems for electric vehicles. These include a microchannel rig for accurate measuring local heat transfer during condensation and flow boiling of low GWP refrigerants and refrigerant mixtures up to high pressure and high temperature and a full tube bank rig for investigating the complex interactions between tube geometry and vapour and liquid flow in real condensers. Several rigs are being used to investigate and optimise highly enhanced finned tubes for increasing heat transfer rates for both internal and external flows and so reducing condenser size. In addition, two calibration baths allow calibration of thermocouples with an accuracy of +/-0.05 K from -15 oC to 200 oC.

Contact: Professor Huasheng Wang

The Makerspace

The Makerspace is an open access workshop for all SEMS and EECS students and staff. It is a space where students can make things, this might be prototyping, model making or simply working on personal projects. The primary aim of the Makerspace is to give students the practical, and creative skills they will require to be effective engineers.

Contact: Mr James Wayland

Thermal Analysis Facility

Differential Scanning Calorimeter.

We have a variety of excellent techniques for analysis the thermal properties of materials such as melting temperature, glass transition temperature, viscosity, thermal expansion and thermo-mechanical properties over a range of temperatures (-150 to 1600C). The techniques include:

- Differential Scanning Calorimetry (DSC)

- Rheometery

- Thermo Gravimetric Analysis (TGA)

- Simultaneous Thermal Analysis (STA)

- Dynamic Mechanical Analysis (DMA)

- Dilatometry.

Contact: Dr Shoghik Hakobyan

Thermoelectric Generator Testing Facility

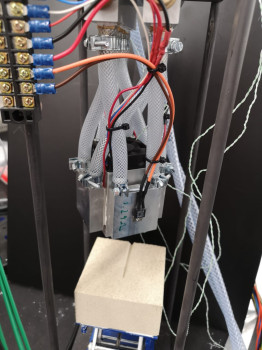

Thermoelectric generator testing

A bespoke thermoelectric generator testing facility is available for testing ceramic and printed thermoelectric generators. It can operate in clamped mode with a feedback system to maintain constant pressure. It can alternatively operated in air-cooled mode using an airjet of defined velocity and feedback-controlled temperature.

Contact: Dr Oliver Fenwick

Thermoelectric Suite

Electrical conductivity and Seebeck measurement (Linseis LSR3)

We house a suite of instruments for the accurate measurement of thermoelectric materials in bulk or thin film form, including:

- Laser Flash Analyzer (Netzsch 453 LFA)

- Electrical conductivity and Seebeck measurement (Linseis LSR3)

- Thin film electrical and thermal conductivity, and Seebeck measurement (Linseis TFA)

Contact:

Prof Michael Reece

Dr Oliver Fenwick

Undergraduate Teaching Labs

We have recently invested £30M in major new teaching laboratories to provide state-of-the-art experimental facilities specifically for teaching.

Opened in 2016 the lab provides a space on the ground floor with step free access and has a height adjustable bench installed for wheelchair users.

Contact: Dr Reshma Tilwani

X-Ray Diffraction Facility

The X-Ray Diffraction Facility (XDF) offers a full diffraction analysis service in materials science, structural chemistry, structural biology and solid state science. The facility is located in the Francis Bancroft building (room G.30) at the Mile End campus, and is operated by the School of Biological and Behavioural Sciences

Contact: Dr Richard Whiteley