Dr Han Zhang

MEng, PhD, PGCAP, FIMMM, FHEA, CEng, CSci

Research Overview

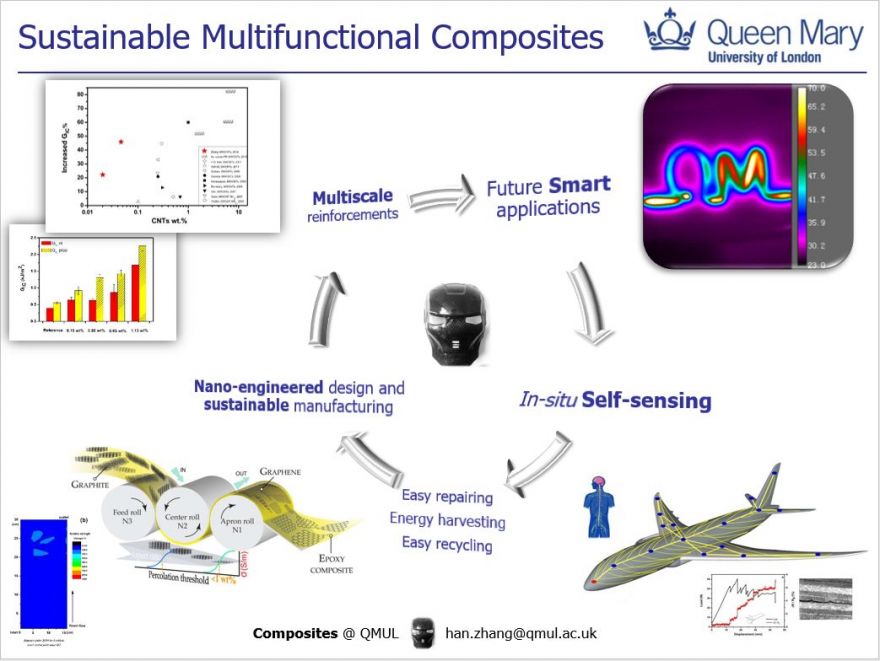

Multifunctional composites, Sustainable manufacturing, Sustainable composites, Easy repairing composites, Polymer composites, Nanocomposites, Polymer processing, Natural fibre composites

Dr. Han Zhang is a Reader in Polymers and Composites at the School of Engineering and Materials Science, Queen Mary University of London. His research motivation comes from the needs for the next generation of sustainable high performance composites with integrated multifunctionalities for future lightweight structural applications. His expertise in the field of composites ranges from design and manufacturing to characterization of advanced composites and nanocomposites, with a special focus on multifunctional composites for future lightweight structural applications. His current research is dedicated to the sustainable development of advanced composites, including energy efficient sustainable manufacturing, and integrated health monitoring and easy repairing functionalities for extended components’ life.

Han received research funding from various sources including EPSRC, Royal Society, EU, Innovate UK, and UK industries. Han has experience from design and processing to advanced characterisations and interpretation of polymer and composite materials, with more than 100 publications in peer-reviewed journals including Advanced Functional Materials, Composites Science and Technology, and ACS Applied Materials & Interfaces.

A brief introduction on some of the research areas can be found below:

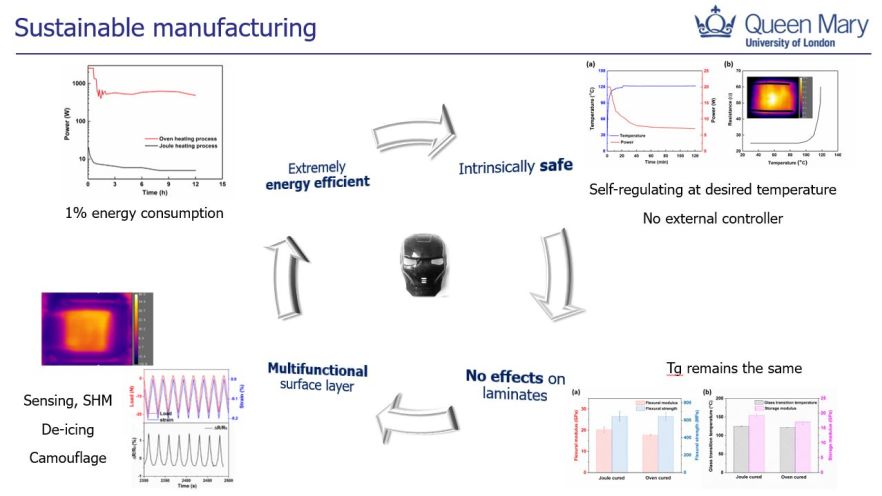

1. Energy efficient composite manufacturing

By utilising smart conductive polymer composites, an extremely energy efficient composite manufacturing has been developed, with a significantly reduced of energy consumption (>90%) compare with traditional oven curing. No effects on the mechanical or thermomechanical properties of the composite laminates, while new functions such as sensing or de-icing have been integrated to the components.

Full compatibility with existing liquid moulding processes such as vacuum assisted resin transfer moulding or resin infusion. Tailored temperature profiles can be achieved to meet the requirements of the resin systems.

Read our published works on this topic at:https://doi.org/10.1016/j.compscitech.2020.108032

https://doi.org/10.1016/j.compscitech.2023.110062

https://doi.org/10.1021/acsami.3c12901

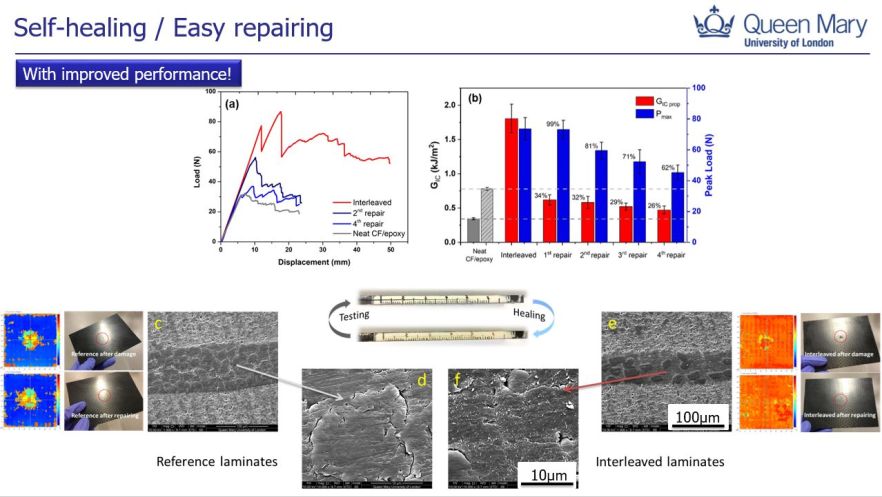

2. Easy repairable composites with extended service life

Based on our expertise of interlaminar toughening in composite laminates, we have developed a simple and effective methodology using commonly used thermoplastic interleaves to achieve repeatable easy-repairing and self-sensing functionalities in carbon fiber/epoxy composites. The resulting composites exhibited enhanced mechanical performance, retaining peak load and interlaminar fracture toughness after four consecutive cycles of damage and healing. The repairable composites maintained their mechanical properties even at high temperatures due to the high glass transition temperature of the thermoplastic. In-situ damage sensing was achieved through the piezoresistive method.

This new approach is fully compatible with current composite manufacturing and offers a solution to extend components’ service life towards a more sustainable development of the composite sector.

Read our published works on this topic at:https://doi.org/10.1016/j.compositesa.2022.107337

https://doi.org/10.1016/j.compositesa.2015.09.024

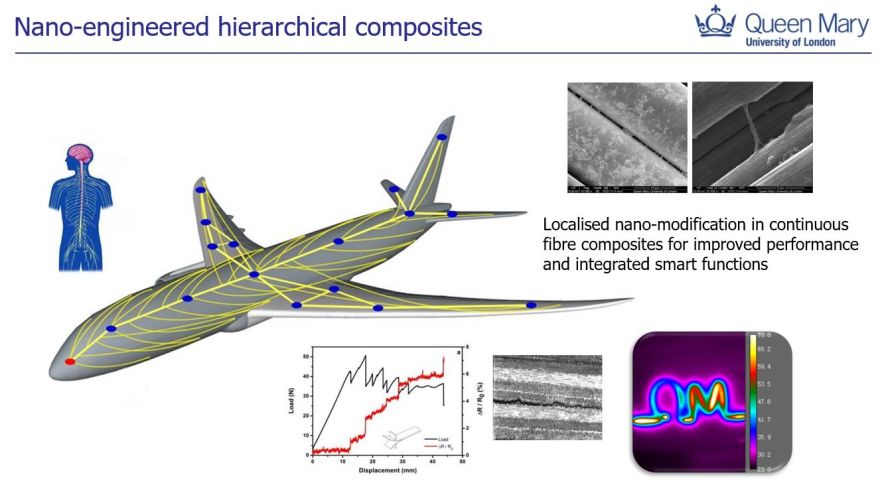

3. Nano-engineered hierarchical composites

With over 10 years of experience in hierarchical composites, we have developed a range of expertise in this research direction, from bottom up and top down manufacturing with localised nano-reinforcements in continuous fibre reinforced composites, to tailored performance and integrated multifunctionalities such as damage sensing, energy harvesting, or significantly enhanced out-of-plane properties.

With only 0.05 wt.% of CNTs introduced into the composites, the Mode-I fracture toughness has been increased by nearly 50%, thanks to the localised deposition of nano-reinforcements into the damage prone zone by scalable methods. New functions such as in-situ damage sensing for structural health monitoring, de-icing, energy harvesting have been successfully developed.

Read our published works on this topic at:https://doi.org/10.1016/j.compositesa.2014.11.029

https://doi.org/10.1016/B978-0-12-819904-6.00009-8

https://doi.org/10.1007/978-3-319-46120-5_5

4. Polymer processing, Conductive Polymer Composites, Nanocomposites

As the first UK Materials department (1967) and one of the five Science Research Council funded Polymer Research Centres in a Materials Department, we have a long standing history and extensive research expertise in polymer and composites processing.

We have a full range of polymer processing equipment, from lab-scale micro-compounder (Xplore MC15 HT microcompounder), pilot-scale twin-screw compounder (Collin ZK25), single screw extruders (equipped with filament and film dies), to injection moulding, solid state drawing and film blowing machines.

A wide range of functional polymer materials have been developed in our lab, such as smart textile with integrated strain sensing capabilities based on conductive polymer composites, as well as highly transparent high performance all-polymer composites.