Research

Carbon Nanotube - Ceramic Composites

| Principal investigator: | Haixue YAN |

| Co-investigator(s): | F. Inam, and Mike REECE |

Using Spark Plasma Sintering (SPS) is is possible to process new composites, with new windows of properties, that were previously not possible to fabricate using conventional processing routes, non-equilibrium composites. When two non-equilibrium phases are processed by conventional sintering they react to form the equilibrium phases. This is used to good advantage in reactive sintering. However, this limits the composites that it is possible to make. Using SPS it is possible to achieve rapid densification with minimal reaction between components. This has been demonstrated in our research on multiferroic composites. Multiferroics materials have coupling of ferroelectric-ferromagnetic-ferroelastic properties, and are of potential interest for new sensors and memory devices. The materials that intrinsically demonstrate these properties are limited and the coupling tends to be weak. One approach to solve this problem is to rapidly co-sinter ferroelectric and ferromagnetic phases into a non-equilibrium composite.

Using Spark Plasma Sintering (SPS) is is possible to process new composites, with new windows of properties, that were previously not possible to fabricate using conventional processing routes, non-equilibrium composites. When two non-equilibrium phases are processed by conventional sintering they react to form the equilibrium phases. This is used to good advantage in reactive sintering. However, this limits the composites that it is possible to make. Using SPS it is possible to achieve rapid densification with minimal reaction between components. This has been demonstrated in our research on multiferroic composites. Multiferroics materials have coupling of ferroelectric-ferromagnetic-ferroelastic properties, and are of potential interest for new sensors and memory devices. The materials that intrinsically demonstrate these properties are limited and the coupling tends to be weak. One approach to solve this problem is to rapidly co-sinter ferroelectric and ferromagnetic phases into a non-equilibrium composite.

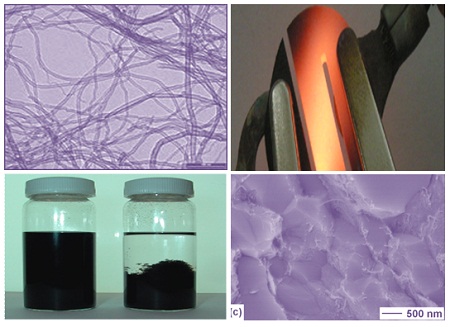

We are using SPS to produce dense, well dispersed, carbon nanotube (CNT) nanocomposites. For the exploitation of these novel nanocomposites, it is crucial not to damage the CNTs while sintering at high temperatures. CNTs possess a heat-sensitive structure that degrades if processed using conventional routes like hot-pressing. SPS can process these nanocomposites in very short intervals of time without structural or chemical degradation of the CNTs. This opens up the possibility of developing ceramics with new electro-mechanical properties and applications, such as, heating elements. Electro Discharge Machinability (EDM), and high electrical and thermal anisotropy.