Research

Spark Plasma Sintering (SPS)

| Principal investigator: | Haixue YAN |

| Co-investigator(s): | F. Inam and Mike REECE |

Ceramics are normally processed by the consolidation of powders by sintering at high temperatures. The time required for this process is usually measured in hours because of the slow rate of heating/cooling of the furnaces used. Spark Plasma Sintering (SPS), as it is commonly referred to, is a rapid sintering process, where the sintering cycle can be completed in minutes. This opens up the possibility of making ceramics with new microstructures and properties.

Ceramics are normally processed by the consolidation of powders by sintering at high temperatures. The time required for this process is usually measured in hours because of the slow rate of heating/cooling of the furnaces used. Spark Plasma Sintering (SPS), as it is commonly referred to, is a rapid sintering process, where the sintering cycle can be completed in minutes. This opens up the possibility of making ceramics with new microstructures and properties.

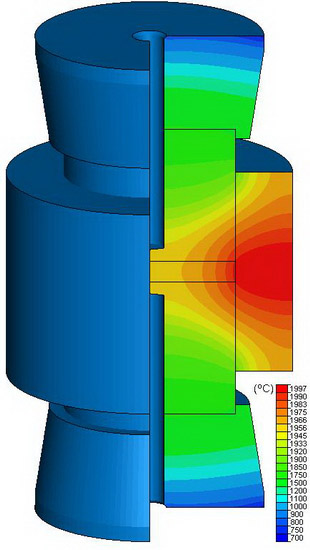

SPS has some similarities to hot-pressing, which involves the application of pressure during sintering. The rapid heating rates in SPS are achieved by the direct Joule heating of the graphite dies in which the ceramics are sintered. This involves pulsed, direct current at low voltages (<10 V) and high currents (typically >1000 A). The furnace at Nanoforce can achieve heating rates of up to ~600 °C/min. Because only the ceramic and die are heated, the cooling rates can be even more rapid because of their low thermal inertia and forced cooling.

SPS has some similarities to hot-pressing, which involves the application of pressure during sintering. The rapid heating rates in SPS are achieved by the direct Joule heating of the graphite dies in which the ceramics are sintered. This involves pulsed, direct current at low voltages (<10 V) and high currents (typically >1000 A). The furnace at Nanoforce can achieve heating rates of up to ~600 °C/min. Because only the ceramic and die are heated, the cooling rates can be even more rapid because of their low thermal inertia and forced cooling.

Working with its academic and industrial collaborators to develop new structural and functional ceramics that can not be prepared using other processing routes. The themes for this research are:

- Nanostructured materials

- Non-equilibrium composites

- Textured materials

- Difficult to densify systems