Research

Leak Prediction for Elastomeric Seals in Oilfield Packers

| Funding source(s): | Schlumberger Technology Corporation |

| | Start: 22-09-2017 / End: 21-03-2021 |

| Directly incurred staff: | Travis Hohenberger |

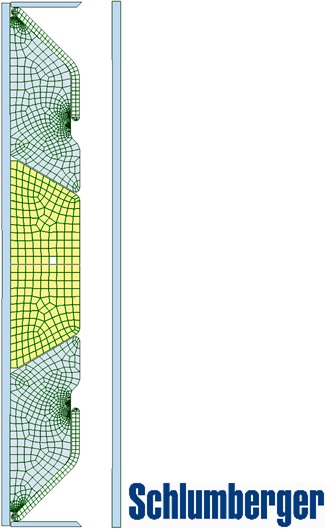

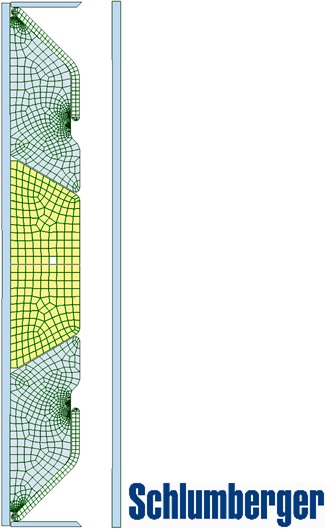

Completion packers, or simply packers, are tools that are used for isolating production zones in oilfield completions. They provide annular seals between two metal tubular components and direct production fluids from a reservoir, up a tubing string, and through a wellhead. The most critical component in a packer is its elastomeric sealing element (see graphic). These are radially deployed by mechanical manipulation or hydraulic actuation of the packer. Following large deformations during setting, they are subjected to pressures in excess of 70 MPa and 230°C and must last up to 20 years in harsh downhole environments. Complex deformations, interactions, and sealing requirements present numerous challenges to the development of packer elements. In an effort to shorten the design lifecycle, this research is developing constitutive models and methods to predict fluid leakage in these seals.