Research

Fatigue of Elastomer Seals

| Funding source(s): | Cameron Flow Control Technology (UK) Ltd |

| | Start: 22-09-2015 / End: 21-09-2018 |

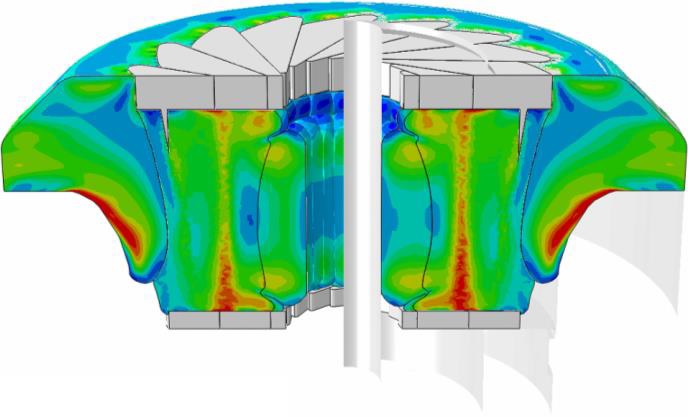

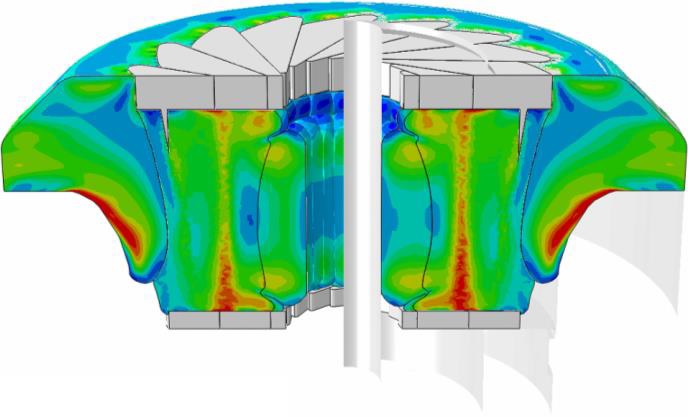

Elastomeric seals generally fail through fracture processes which can either initiate from inherent internal flaws or through damage induced surface flaws. To study the fracture of these flaws in complex components, computational approaches provide the only viable option as they allow the tearing energy to be evaluated directly at a specific crack located anywhere in the component. This is a complex process, involving an understanding of both elastomer based fracture mechanics and non-linear computational modelling. Due to this, when evaluating seal designs, it is common for seal failure to be approached through a critical stress or strain criterion, even though this has no basis in fracture mechanics. As of yet there has been little work on applying fracture mechanics approaches to the type of problems exhibited in seals, in any industry let alone the Oil and Gas industry. This was addressed in this work.