Research

MASSIVE Materials

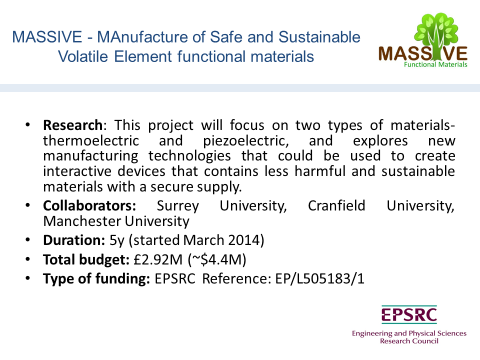

| Principal investigator: | Mike REECE |

| Funding source(s): | E.P.S.R.C. |

| Start: 31-03-2014 / End: 30-09-2019 | |

| Amount: £702,880 |

The MASSIVE project will develop scale-up manufacturing capability and know-how for the synthesis, processing and manufacture of un-commercialised thermoelectric, piezoelectric and related materials and devices, which contain volatile and air-sensitive elements and compounds, with engineered nano- and non-equilibrium phases and structures.

The MASSIVE project will develop scale-up manufacturing capability and know-how for the synthesis, processing and manufacture of un-commercialised thermoelectric, piezoelectric and related materials and devices, which contain volatile and air-sensitive elements and compounds, with engineered nano- and non-equilibrium phases and structures.

This will be delivered through a series of related objectives:

- Scaling-up synthesis of particulate materials, including novel composite and nanostructured materials. The manufacture of the feedstock particulate materials in sufficient quantity, composition and purity, is an integral part of the manufacturing chain. Solid state, wet and controlled atmosphere synthesis routes will be scaled-up to determine the requirements for effective large scale production.

- Reducing lead time to market through exploration of high throughput manufacturing techniques for films and bulk materials

- Management of high temperature thermal treatments to prevent near-surface degradation (volatisation) of materials, maintenance of critical nano/microstructures, and co-processing. Manufacturing techniques will be required to balance the conflicting demands of controlling the nano- and micro-structure while at the same time achieving high production outputs. Spark plasma sintering will be explored for bulk materials while atmosphere controlled rapid-sinter processing in combination with printing technologies will be explored for thick film materials.

- Understanding the role of manufacturing on the materials behaviour during machining (e.g. during cutting, grinding, polishing). The mechanical integrity of the functional materials will be evaluated as a function of the manufacturing route and conditions. This will identify potential knock-on effects further along the manufacturing chain as a result of substituting materials.

- Design of robust interfaces for electrodes, protective coatings, and joints for in-service performance. The interfacial bonding behaviour between dissimilar materials will be characterised to identify and manage the changes required in subsequent processing stages during device manufacture that will arise as a result of substituting materials. This understanding is required where electrodes and protective coatings are required or where two materials must be joined in order to realise the final device.

- Incorporation of risk management within the manufacturing design stage to ensure the developed processes are fit-for service. To ensure that new long term problems relating to safety, security of supply and sustainability are not likely to be introduced into the new manufacturing processes, the occupational, consumer, and environmental risk landscape of current and developed manufacturing processes and materials will be compared.

- Knowledge transfer through industrial collaboration, dissemination and networking. Increasing the level of technology transfer and training within the community and manufacturing supply chain will be driven by a proactive outreach dissemination programme based on the long-term experiences of the researchers of academic-industrial collaborations.