Research

Understanding of titanium machining using minimal quantity lubrication (MQL) (Airbus contract for Research Fellow)

| Funding source(s): | Air Bus Uk |

| | Start: 19-07-2010 / End: 18-10-2010 |

| | Amount: £22,791 |

This research (contract) was supported by Airbus UK. The aim of the project is to understand the influence of MQL on cutting tool wear mechanism to enable high performance cutting of Ti-6Al-4V.

The project objectives in the next three months can be laid out as follows:

(1) Literature review. To perform a thorough literature review on wear mechanism, modelling of cutting force, cutting temperature and tool wear, MQL process in machining of Ti-6Al-4V.

(2) Cutting force coefficients. Establish cutting force coefficients on the baseline indexable cutting tool in order to model cutting forces.

(3) Tool wear mechanism. Establish understanding of tool wear mechanism (flank and notch) in MQL and flood cooling.

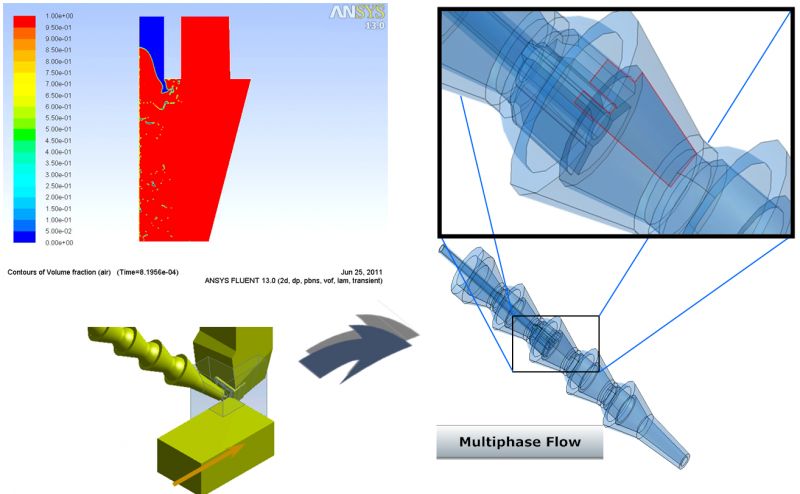

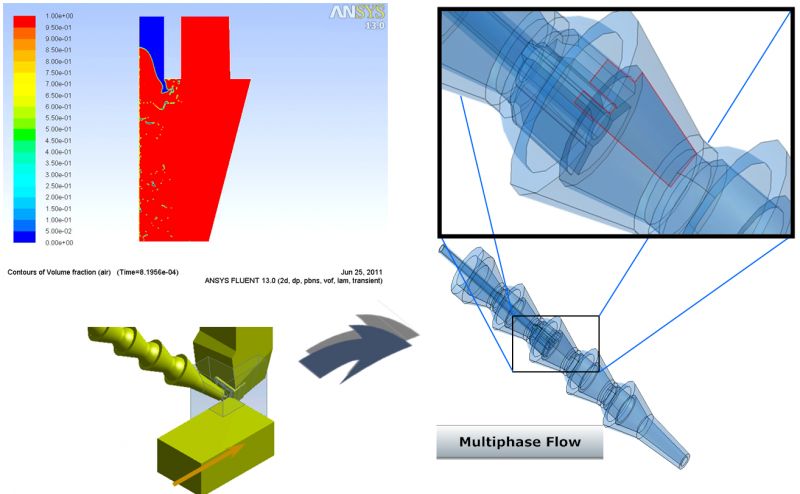

(4) Modelling. Establish 2D/3D models to model cutting forces, cutting temperatures and tool wear.