Research

Graphene Nanocomposites

| Principal investigator: | |

| Co-investigator(s): |

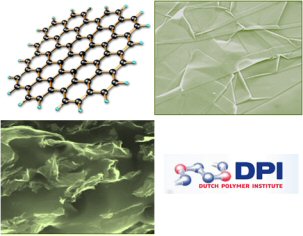

Graphene is a one-atom-thick planar sheet of sp2-bonded carbon atoms that are densely packed in a honeycomb crystal lattice. It can be visualized as an atomic-scale chicken wire made of carbon atoms and their bonds. Though graphene and carbon nanotubes are nearly identical in their chemical makeup and mechanical properties, graphene has the potential to out-perform carbon nanotubes in polymer composites. Similar to single-walled carbon nanotubes, graphene is incredibly strong, but they may form a stronger interface with the polymer as the planar graphene sheet has considerably more contact area with the polymer material than the hollow carbon nanotubes. In the case of nanotubes the polymer chains are unable to enter the interior of the nanotubes meaning that only one side of the filler is in contact with the polymer, while in the case of graphene both the top and bottom surfaces of the sheet can be contact with the polymer matrix. Graphene possesses a 2D geometry compared to the 1D geometry for nanotubes and 3D geometry for (highly structured) carbon black. This 2D geometry may have some addition benefits as the larger surface area could be more efficient in deflecting cracks in brittle polymers leading to improved toughness, while they may also be more effective in improving barrier properties and as flame retardants.

Graphene is a one-atom-thick planar sheet of sp2-bonded carbon atoms that are densely packed in a honeycomb crystal lattice. It can be visualized as an atomic-scale chicken wire made of carbon atoms and their bonds. Though graphene and carbon nanotubes are nearly identical in their chemical makeup and mechanical properties, graphene has the potential to out-perform carbon nanotubes in polymer composites. Similar to single-walled carbon nanotubes, graphene is incredibly strong, but they may form a stronger interface with the polymer as the planar graphene sheet has considerably more contact area with the polymer material than the hollow carbon nanotubes. In the case of nanotubes the polymer chains are unable to enter the interior of the nanotubes meaning that only one side of the filler is in contact with the polymer, while in the case of graphene both the top and bottom surfaces of the sheet can be contact with the polymer matrix. Graphene possesses a 2D geometry compared to the 1D geometry for nanotubes and 3D geometry for (highly structured) carbon black. This 2D geometry may have some addition benefits as the larger surface area could be more efficient in deflecting cracks in brittle polymers leading to improved toughness, while they may also be more effective in improving barrier properties and as flame retardants.

Our work focuses on creating bioinspired layered nanocomposite films that exhibit a “brick and mortar” structure using, among others, layer-by-layer spraying, pressing-and-folding, and multilayer extrusion technologies. Applications are foreseen in areas such as transparent conductive flexible films, high strength polymer films and barrier films.