Research

Natural Fibre Reinforced Plastics

| Principal investigator: | A. Scherillo |

| Co-investigator(s): | H. Patel and |

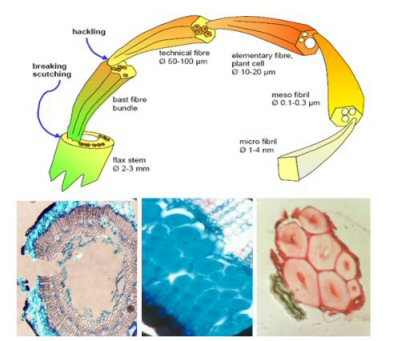

Plant fibres such as flax, hemp, ramie and kenaf are being evaluated as environmentally friendly and low-cost alternatives for glass fibres in engineering composites. Ligno-cellulose fibres from annual crops have a higher aspect ratio than wood fibres and are therefore more effective as reinforcements for composites. Natural fibres have a number of advantages over glass fibres as they are renewable, low cost and lightweight. They can help reduce CO2 emissions by being entirely compostable, and through weight reduction, which in automotive applications helps improve fuel economy. Their production and end-of-life incineration are less energy intensive than glass fibers, which also results in lower emissions. The group’s has been active in the area of natural fibre composites for over 15 years and has focused on a number of critical issues such as processing and compounding, mechanical properties (i.e. strength and toughness), fibre-matrix adhesion, recyclability, moisture resistance, fire retardancy and durability. Research has focused on a wide range of composite systems including sheet moulding compounds (SMC) made from hemp fibres and unsaturated polyester, and natural fibre mat reinforced thermoplastics (NMT) for compression moulding applications based on polypropylene (PP) and non-woven hemp or flax mats. Short- and long fibre thermoplastics (LFT) for injection moulding applications have been developed based on thermoplastics such as PP, POM and PBT. The potential of recycled plastics has also been evaluated to further lower the environmental impact of these composites or to use plastics made entirely from sustainable resources such as such as polylactic acid (PLA), polyhydroxybutyrate (PHB) or thermoplastic starch.

Plant fibres such as flax, hemp, ramie and kenaf are being evaluated as environmentally friendly and low-cost alternatives for glass fibres in engineering composites. Ligno-cellulose fibres from annual crops have a higher aspect ratio than wood fibres and are therefore more effective as reinforcements for composites. Natural fibres have a number of advantages over glass fibres as they are renewable, low cost and lightweight. They can help reduce CO2 emissions by being entirely compostable, and through weight reduction, which in automotive applications helps improve fuel economy. Their production and end-of-life incineration are less energy intensive than glass fibers, which also results in lower emissions. The group’s has been active in the area of natural fibre composites for over 15 years and has focused on a number of critical issues such as processing and compounding, mechanical properties (i.e. strength and toughness), fibre-matrix adhesion, recyclability, moisture resistance, fire retardancy and durability. Research has focused on a wide range of composite systems including sheet moulding compounds (SMC) made from hemp fibres and unsaturated polyester, and natural fibre mat reinforced thermoplastics (NMT) for compression moulding applications based on polypropylene (PP) and non-woven hemp or flax mats. Short- and long fibre thermoplastics (LFT) for injection moulding applications have been developed based on thermoplastics such as PP, POM and PBT. The potential of recycled plastics has also been evaluated to further lower the environmental impact of these composites or to use plastics made entirely from sustainable resources such as such as polylactic acid (PLA), polyhydroxybutyrate (PHB) or thermoplastic starch.

More recently the group has focused on the development of ‘high-performance natural fibre composites’ based on textile preforms. For this low-twist flax yarns have been developed in collaborative R&D programmes together with industry. These yarns are based on long, aligned natural fibres to fully exploit the inherent mechanical properties of the fibres in load-bearing applications. The team has also been involved in the development of a new commingled low-twist yarn based on a flax/PP or flax/PLA fibre blend. The technology which is now commercialized under the name Biotex™ results in yarns that are highly aligned to give up to 50% better fibre efficiency over conventional twisted yarns. These low-twist yarns are also easier to impregnate, giving improved fibre/matrix interaction and better performance and can be processed by vacuum bag consolidation or press moulding. The product is the direct result of the COMBINE project co-funded by EPSRC and the UK Technology Strategy Board's Collaborative Research and Development programme.

More recently the group has focused on the development of ‘high-performance natural fibre composites’ based on textile preforms. For this low-twist flax yarns have been developed in collaborative R&D programmes together with industry. These yarns are based on long, aligned natural fibres to fully exploit the inherent mechanical properties of the fibres in load-bearing applications. The team has also been involved in the development of a new commingled low-twist yarn based on a flax/PP or flax/PLA fibre blend. The technology which is now commercialized under the name Biotex™ results in yarns that are highly aligned to give up to 50% better fibre efficiency over conventional twisted yarns. These low-twist yarns are also easier to impregnate, giving improved fibre/matrix interaction and better performance and can be processed by vacuum bag consolidation or press moulding. The product is the direct result of the COMBINE project co-funded by EPSRC and the UK Technology Strategy Board's Collaborative Research and Development programme.