Research

Development of bioinspired, lightweight self-healing composite synthetic foam core sandwich structures for blast mitigation

| Principal investigator: | Tao LIU |

| Funding source(s): | DSTL |

| Start: 01-09-2016 / End: 30-06-2017 | |

| Amount: £92,000 | |

| Directly incurred staff: | Li Guan |

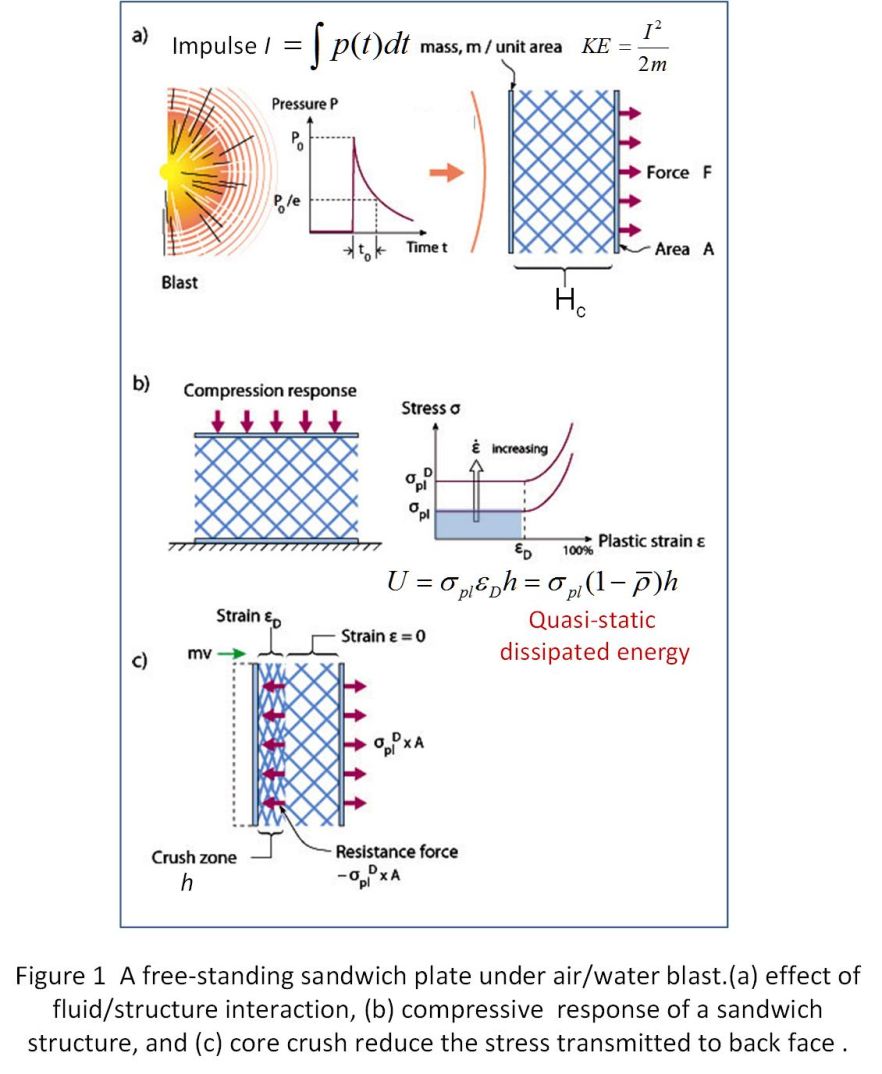

Sandwich structures are made of low density, porous cores sandwiched between high densities, stiff facesheets. Beams and panels under sandwich construction can offer lightweight solutions with larger bending stiffness, greater energy absorption ability and better multifunctional performance in comparison with those under the solid monolithic construction with same mass. There has been growing interest to apply lightweight polymer composite sandwich structures for marine application or military vehicle structures. Sandwich design concept has recently been explored in development of highly efficient blast resistant structures.

Motivated by the self-healing mechanisms in bio-systems such as bones and tissues, the project seeks to develop novel, lightweight self-healing polymeric foam core sandwich structures for blast/impact mitigation application.The sandwich core is made of a synthetic foam, i.e. a closed cell or open cell polymeric matrix foam reinforced by glass beads and short carbon fibres, and the facesheets are made of carbon / glass fibre reinforced composites. The glass beads embedded in the synthetic foam core have three functions, i.e. strengthening, blast mitigation and self-healing.