News

No ovens? No problems! - Scientists develop extremely energy efficient manufacturing method for natural fibre composites

4 May 2023

No more worries about high energy bills for composites manufacturing!

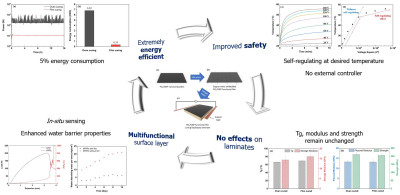

Materials scientists at Queen Mary University of London have developed an innovative and energy-efficient method to manufacture natural fibre composites without the need for conventional ovens. This out-of-oven method is based on a smart nanocomposite film that heats and cures the laminates at the desired temperature, reducing energy consumption by up to 95% compared to traditional oven curing methods.

The smart biopolymer layer developed in this work provides a self-regulating heating function that ensures the safety of the exothermic reaction of thermoset curing processes without the risk of overheating. The out-of-oven (OoO) Joule heating method uses efficient heat transfer by conduction from the film to the laminate, ensuring high energy efficiency alongside the preservation of thermomechanical and mechanical properties of the natural fibre composites.

"No ovens? No problems! We can make high-quality natural fibre composites out-of-oven," said Dr Han Zhang, Senior Lecturer at QMUL who leads the study and the EPSRC project "ESTEEM" (EP/V037234/1). "With the growing demand for using composite materials, we want to reduce the overall environmental impacts of the composites sector, contributing towards a more sustainable development of the field".

The embedded nanocomposite surface film on the cured laminate also provides real-time deformation and damage sensing capabilities and an enhanced water barrier property, thus prolonging the service life of the natural fibre composites. This breakthrough opens up new opportunities for sustainable composites manufacturing, with significantly reduced energy consumption and integrated multifunctionalities.

The work has been published in one of the top journals of the field, Composites Science and Technology, with open access supported by the UKRI - read the full article - 10.1016/j.compscitech.2023.110062

The development of this energy-efficient OoO curing method is a significant milestone towards sustainable composites manufacturing, without affecting composite internal structures or sacrificing their performance. With further research, this method can be applied to other composite systems, leading to a more sustainable and eco-friendly future for manufacturing.

| Contact: | Han Zhang |

| Email: | han.zhang@qmul.ac.uk |

| Website: | |

| People: | Han ZHANG |

| Research Centres: | Sustainable Engineering Intelligent Transport |

Updated by: Han Zhang