News

Burnt nut shells in water filters shown to cut E. coli by 96%: Dr Roberto Volpe's research features in Daily Telegraph

20 February 2023

Ground-breaking work lights a path for environmental applications as charcoal made from burnt nut shells could help eradicate superbugs from hospital wastewater, experts believe

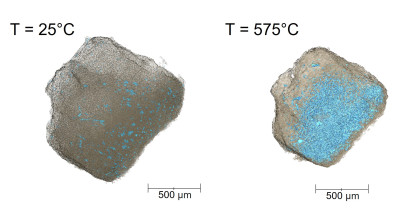

Dr Roberto Volpe and his team at Queen Mary University of London and University College London in collaboration with the UK’s national synchrotron, Diamond Light Source, have for the first time imaged the porosity of biochars via unprecedented operando experiments at Diamond. Dr Volpe’s work to overcome existing knowledge gaps in the thermochemical decomposition of biomass could enable production of tailor-made bio-chars for high priority environmental applications. With the support from a European Horizon 2020 grant called ExPaNDs- European Open Science Cloud (EOSC) Photon and Neutron Data Service - Diamond has worked with Dr Volpe on a new specific data intensive technique used at the synchrotron to accelerate access to results.

Dr Volpe’s current research involves examining and identifying the chars created from raw biomass of almond and walnut shells as their porosity is key to environmental applications. The ability to customise the morphology of these chars could herald a great breakthrough to help address global challenges by creating inexpensive and renewable solutions to energy storage, catalysis, water and soil remediation. Tracking the morphology of biomass during biochar production is the first step towards achieving this.

“What we do is simple as we take almond and walnut shells and we put them through pyrolysis to create a char biomass – the study of carbonisation of biomass essentially reflects techniques dating back to the beginning of mankind by turning wood into charcoal. However, in our study, the process is monitored every step of the way and what we are interested in, is the porosity that is being created. By accurately heating, we can form up to more than a thousand square metres of accessible surface area in the intricate network of pores inside a single gram of formed biochars.”

He adds: “Applications for this work are many as contaminants (bacteria, metals, polluting molecules) or ions (in the case of energy storage, for example) can be carried by water (or by an electrolyte) into the intra-particle pore network, and they can be trapped there. Tracking the evolution of this pore network as we heat the biomass particles is key and the real novelty of this work.”

--

Clipping from Daily Telegraph available on request.

| People: | Roberto VOLPE |

| Research Centre: | Sustainable Engineering |

Updated by: Roberto Volpe