News

New research powers next-gen batteries for cheaper, faster-charging and longer range electric vehicles

27 October 2025

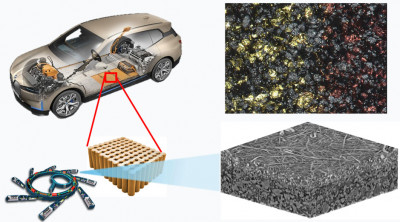

New battery research led by Queen Mary University of London demonstrates that a double-layer electrode design, guided by operando imaging, shows remarkable improvements in the cyclic stability and fast-charging performance of automotive batteries, with strong potential to reduce costs by 20–30%.

The study, published in Nature Nanotechnology, was led by Dr Xuekun Lu, Senior Lecturer in Green Energy at the School of Engineering and Materials Science.

The researchers introduced an evidence-guided double-layer design for silicon-based composite electrodes, to tackle key challenges in the Si-based electrode — a breakthrough with strong potential for next-generation high-performance batteries.

Research Lead Dr Xuekun Lu said: “This study opens new avenues for innovating 3D composite electrode architectures, pushing the boundaries of energy density, cycle life, and charging speed in automotive batteries, and thereby accelerating large-scale electric vehicle adoption.”

Since the early adoption of electric vehicles around 15 years ago, automotive battery development has been driven by increasing demands for extended driving range and rapid charging.

Silicon electrodes can provide 10 times higher theoretical capacity and faster charging, but their large-scale deployment is held back by substantial volume changes of up to 300% during charge/discharge cycles. This means they degrade quickly and don’t last long.

Assisted by multiscale multimodal operando imaging techniques, this research reveals unprecedented insights into the electro-chemo-mechanical processes of the graphite/silicon composite electrodes. Guided by these improved mechanistic understandings, a novel double-layer architecture is proposed, which addresses key challenges in material design, exhibiting significantly higher capacity and lower degradation compared to conventional formulations.

Professor David Greenwood, CEO of the WMG High Value Manufacturing Catapult Centre, commented: "This study offers a much deeper understanding of the way in which battery microstructure affects their performance and degradation, and will provide a basis for better battery design in the future."

| Contact: | Xuekun Lu |

| Email: | xuekun.lu@qmul.ac.uk |

| Website: | |

| People: | Xuekun LU |