Prof James Busfield

FREng, MA, PhD, CEng, FIMMM, FHEA

Research Funding

On this page:

- Current Funded Research Projects

- Current PhD Studentship Projects

- Previous Funded Research Projects

- Previous PhD Studentship Projects

- Other Research Projects

Current Funded Research Projects

EPSRC Sustainable Manufacturing Call - Circular economy elastomer productsFunding source: EPSRC Engineering and Physical Sciences Research CouncilStart: 18-07-2022 / End: 17-07-2025 Amount: £401,990 |

Circular economy elastomer productsFunding source: EPSRC Engineering and Physical Sciences Research CouncilStart: 01-02-2022 / End: 31-01-2025 Amount: £395,434 The sustainability of elastomer industry is under huge scrutiny as many polymers are derived from fossil fuels and a large amount of rubber waste generated annually is not recycled. This research programme will develop novel circular economy elastomer products from renewable biobased feedstocks, with zero waste and high resource efficiency. |

2023 Bridgestone Elastomer ResearchFunding source: Bridgestone CorporationStart: 01-09-2023 / End: 31-08-2024 Amount: £4,409 |

Creative Clusters Fashion in Smart TextileFunding source: AHRC Arts and Humanities Research CouncilStart: 31-10-2018 / End: 31-05-2024 Amount: £345,900 The Business of Fashion, Textiles and Technology (BFTT) is a five-year industry-led project, which focusses on delivering sustainable innovation within the entire fashion and textile supply chain. The aim is to foster a new, creative business culture in which fashion, textiles and technology businesses can use R&D as a mechanism for growth. |

Current PhD Studentship Projects

Aston Martin F1 - Elastomer Materials Collaboration : Optimisation of Tyre Wear PerformanceFunding source: Aston Martin Formula One TeamStart: 20-09-2021 / End: 31-12-2025 Aston Martin F1 - Elastomer Materials Collaboration : Optimisation of Tyre Wear Performance |

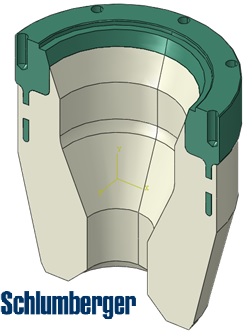

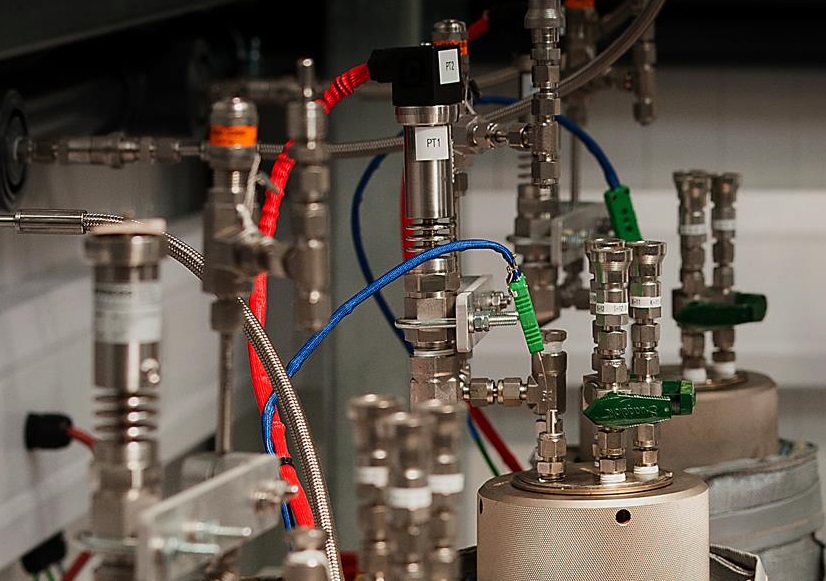

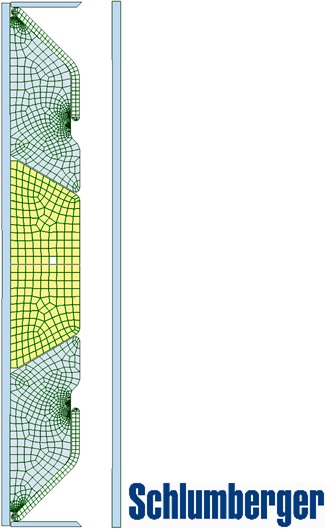

iCASE - Schlumberger 2 - Filler ReinforcementFunding source: Schlumberger LimitedStart: 01-04-2021 / End: 31-03-2025 this project examines the elastomer composites used in dynamic seals for geothermal drilling |

iCASE - Schlumberger 1 - Ageing studyFunding source: Schlumberger LimitedStart: 01-04-2021 / End: 31-03-2025 This project examines the ageing and degradation of elastomer used in dynamic seals in geothermal drilling platforms. |

SRI - Elastomer Materials CollaborationFunding source: Sumitomo Corporation EuropeStart: 20-09-2021 / End: 19-03-2025 SRI - Elastomer Materials Collaboration |

Previous Funded Research Projects

2022 Bridgestone Elastomer ResearchFunding source: Bridgestone CorporationStart: 01-10-2022 / End: 30-09-2023 |

Graphene Flagship Core Project 3Funding source: EU Commission - Horizon 2020Start: 01-04-2020 / End: 31-03-2023 This grant will cofund the establishing of a mini-CDT with 5 PhD studentships in Graphene materials at QMUL. |

Smart rope with sensing capability using multifunctional materials (SENSING ROPE)Funding source: Royal Academy of EngineeringStart: 29-01-2021 / End: 22-01-2023 This Royal Academy of Engineering funded industry fellowship will explore the use of novel polymer nanocomposites as embedded sensors in ropes. |

Bridgestone Elastomer Research (18)Funding source: Bridgestone CorporationStart: 01-10-2021 / End: 30-09-2022 |

Recycle Al cans for fashion productsFunding source: AHRC Arts and Humanities Research CouncilStart: 08-06-2020 / End: 07-12-2021 The principal aim of the project is to deliver a renewably powered machine that can transform rescued aluminium cans into hardware. We are working with Elvis & Kresse to develop an Open Source micro solar forge. The specific goal was to create an inexpensive technology that would allow Elvis & Kresse to collect littered aluminium cans and transform them into hardware (buckles, D-Rings etc.) for their range. https://bftt.org.uk/funded_project/elvis-kresse-metal-forge-elvis-and-kresse/ |

Bridgestone Elastomer Research (17)Funding source: Bridgestone CorporationStart: 01-10-2020 / End: 30-09-2021 |

Physical Ageing of RubberFunding source: Bridgestone CorporationStart: 01-10-2019 / End: 30-09-2020 Carbon black filled elastomers composites are widely used in engineering applications. Their performance changes with time both from changes in their operating temperature and as a consequence of various different ageing mechanisms. This project focuses on modelling the effects of physical ageing on the mechanical properties. |

Bridgestone Rubber ResearchFunding source: Bridgestone CorporationStart: 01-10-2018 / End: 30-09-2019 This grant supports the work of the soft matter group in investigating the nature of the polymer filler interactions that are present in tyre compounds. |

Schlumberger PDRA Project FundingFunding source: Schlumberger LimitedStart: 24-09-2018 / End: 23-03-2019 This grant is used to employ a PDRA, Dr Richard Windslow, to apply the knowledge he gained during his PhD program focused on Dynamic Seals and apply this towards a RCD Sealing Element. It will extend the modelling capabilities at Schlumberger and address challenges encountered to date for Sealing Element modelling. |

Bridgestone Rubber Research ProjectFunding source: Bridgestone CorporationStart: 01-10-2015 / End: 30-09-2018 This grant supported the work of the soft matter group in investigating changes to the nature of the polymer filler interactions in rubber compounds under strain. |

Effects of Sour Gas Ageing on Cross-linked HNBRFunding source: ARTISStart: 01-06-2015 / End: 31-05-2017 This project funded a PDRA to examine the effects of sour gas ageing on crosslinked HNBR polymer. It focused on the changes to the network structure and their relationship to changes in their physical properties. |

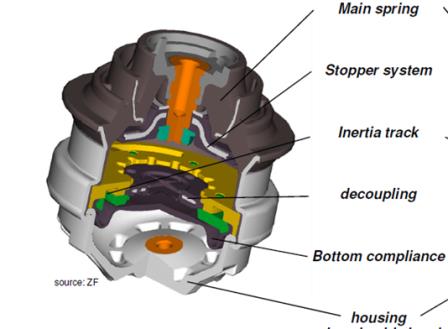

Hyundai Rubber Research ProjectFunding source: Hyundai Motor Company / Hyundai Motor CompanyStart: 01-06-2013 / End: 31-05-2016 Hyundai enhanced their elastomer modelling capabilities and investigated the mechanisms that result in changes in behaviour with ageing of hydraulic elastomer mounting systems |

Characterisation and Properties of Sticky Layer Wear DebrisFunding source: Sumitomo Rubber IndustriesStart: 01-05-2015 / End: 28-02-2016 This project funded a PDRA to examine the transitions from particulate wear behaviour to sticky wear behaviour in a range of novel tyre tread compounds. |

Bridgestone Rubber Research ProgrammeFunding source: Bridgestone CorporationStart: 01-10-2014 / End: 30-09-2015 This grant supported the work of the soft matter group in investigating the nature of the polymer filler interactions using dielectric spectroscopy. |

Viscoelastic Characterisation of Elastomer MaterialsFunding source: Schlumberger Cambridge Research LtdStart: 01-12-2014 / End: 30-04-2015 This project funded a PDRA, Dr Lewis Tunicliffe, to examine the viscoelastic behaviour of HNBR elastomer compounds used in dynamic sealing applications in the oil and gas sector. The aim being to create a dataset of properties to accurately model the materials behaviour for use in finite element modelling. |

Predicting the Failure of Elastomeric Engine Mounts in ServiceFunding source: Hyundai Motor CompanyStart: 01-06-2013 / End: 31-05-2014 A typical automotive engine is supported by three separate mounting systems. This project examined the interaction of various different mechanical, thermal and chemical degradation mechanisms on the behaviour of a hydraulic engine mount. |

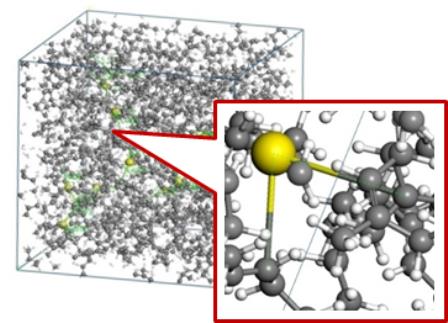

Molecular Dynamics Simulation of Elastomers and Elastomer-Filler InteractionsFunding source: Hyundai Motor CompanyStart: 01-06-2013 / End: 31-05-2014 This programme aims to use both atomistic and course grained molecular dynamics to model the behaviour of rubber materials under strain. The aim being to use the models to develop better constitutive models to create more robust and realistic continuum mechanics models. |

Previous PhD Studentship Projects

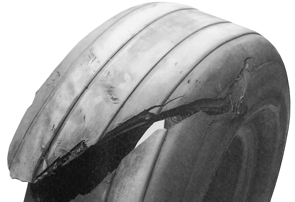

Fracture Behaviour in Off Road TyresFunding source: Birla Carbon USA Inc.Start: 01-08-2019 / End: 31-01-2024 Off-road car tyres are used on harsh surface conditions and experience high stresses making them susceptible to failure mechanisms such as cut and chip. This project will improve the life span on treads used on off road tires by coupling materials innovations and materials characterization of different carbon black grades. |

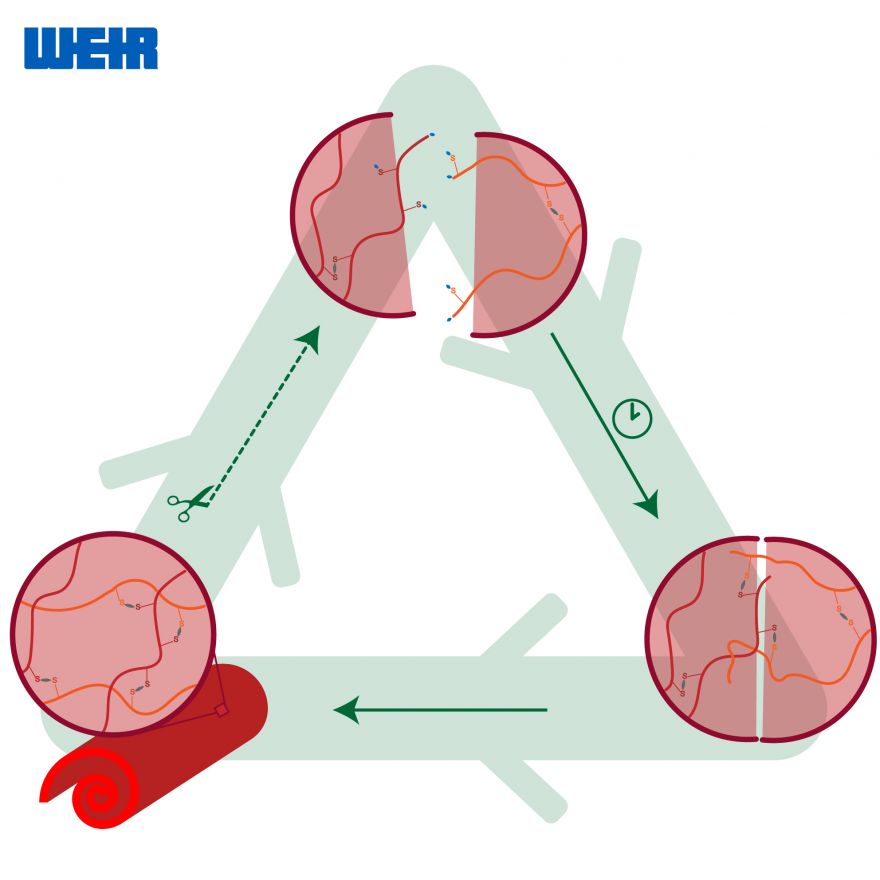

Self Healing Elastomer MaterialsFunding source: Weir Group PlcStart: 01-05-2019 / End: 31-10-2022 Pumps used in slurry applications are typically lined with rubber liners to improve product lifetimes. This project aims to develop an intrinsic self-healing mechanism that can reduce the erosion rate of these liners. |

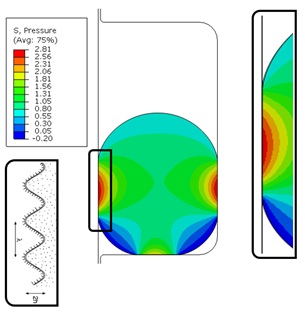

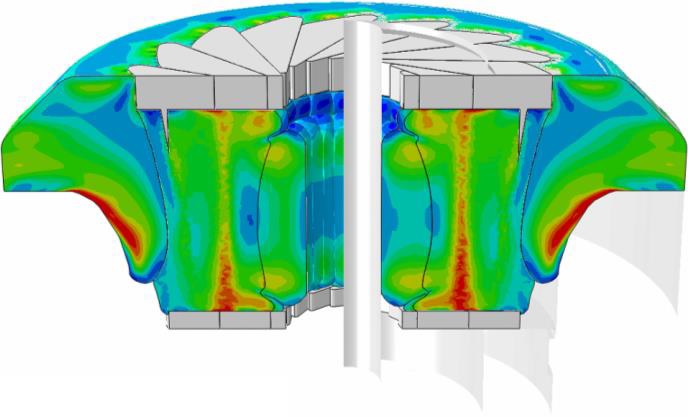

Leak Prediction for Elastomeric Seals in Oilfield PackersFunding source: Schlumberger Technology CorporationStart: 22-09-2017 / End: 21-03-2021 Packers are used to isolate production zones in oilfield completions. These elastomeric sealing elements undergo large deformations during setting and must survive down hole at pressures above 70MPa and temperatures above 230°C. This project will reduce design lead-times by developing constitutive models and methods to predict fluid leakage in these seals. |

Elastomer Friction in Subsea Sealing ApplicationsFunding source: Schlumberger LimitedStart: 22-09-2017 / End: 21-03-2021 This PhD project aims to improve the design approaches used in Schlumberger to model the behaviour of elastomers for subsea sealing applications. It will initially focus on modelling friction interactions and then consider the material behaviour. |

Ageing and Fatigue of Dynamic Elastomeric SealsFunding source: E.P.S.R.C. / Schlumberger Cambridge Research LtdStart: 01-10-2015 / End: 30-09-2020 Dynamic seals such as those used in O&G drilling applications feature high strains, high strain rates, wide temperature ranges, contact with water and organic solvent mixes at large pressures. This project was to build a model to understand the behaviour of the elastomer materials found in mud motor stators. |

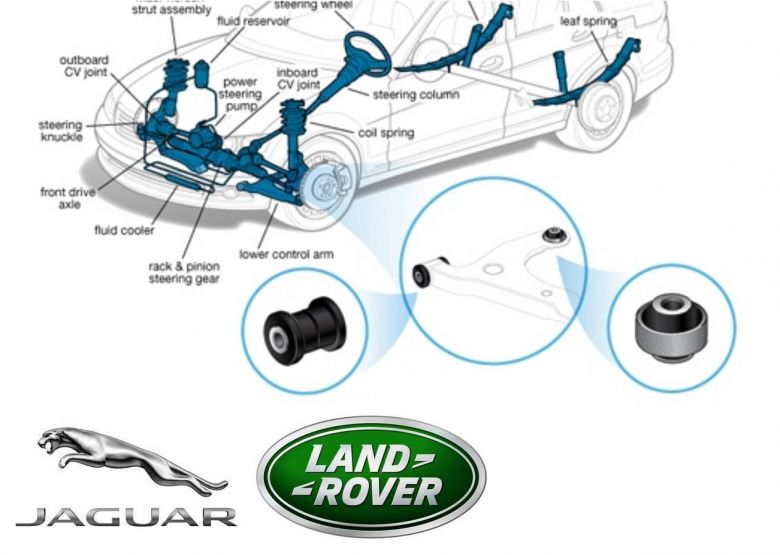

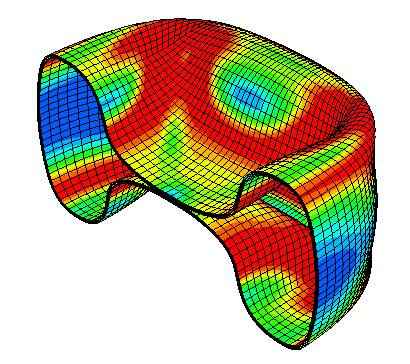

Viscoelastic Modelling of Vehicle Suspension ComponentsFunding source: Jaguar Land Rover LtdStart: 01-09-2014 / End: 31-12-2018 The project derived constitutive models that were valid over the entire service load and strain rate range for elastomer materials that are commonly used in vehicle suspensions. |

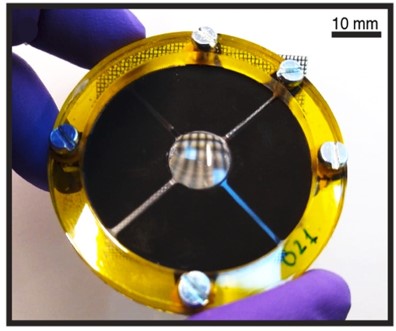

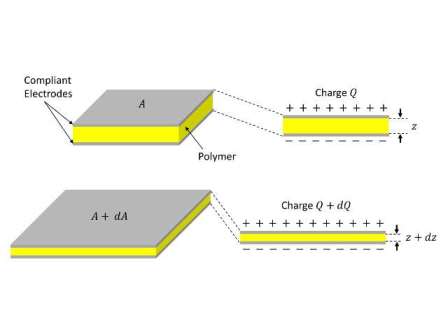

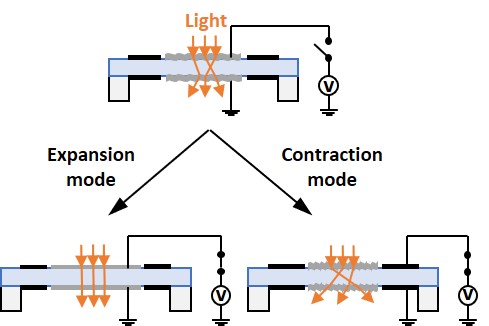

The Development of Dielectric Elastomer Actuator DevicesFunding source: European CommissionStart: 01-01-2015 / End: 31-12-2018 This PhD studentship was part of the MICACT Marie Sklodowska-Curie Action Innovative Training Networks (ITN). Our contribution was to create a range of different Dielectric Elastomer Actuator devices for optical, haptic and bio-engineering applications. |

Fatigue of Elastomer SealsFunding source: Cameron Flow Control Technology (UK) LtdStart: 22-09-2015 / End: 21-09-2018 This project studied the fracture behviour in complex seals used in the Oil and Gas industry. The approach used finite element techniques to evaluate the tearing energy for specific cracks located anywhere in the component and required detailed characterisation of the material tear and fatigue behaviour. |

Fatigue Properties of Fibre Reinforced Timing BeltsFunding source: NGF Europe LtdStart: 01-10-2014 / End: 30-09-2017 Glass fibres are typically used as a reinforcement in most elastomer timing belts. Unidirectional carbon fibre is an alternative reinforcement material. This project examines the interaction between both types of cord reinforcements and the HNBR as well as the fatigue behavior of the composite structures. |

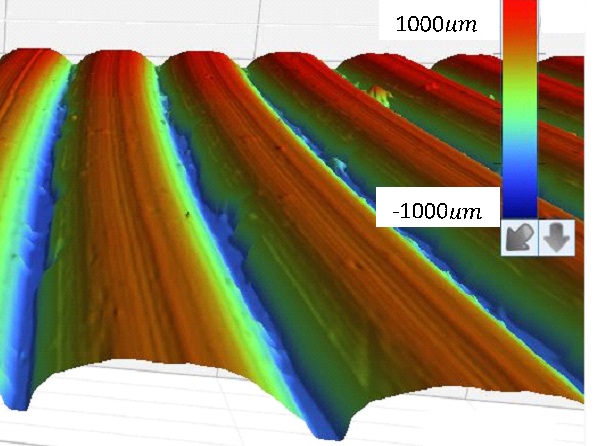

Modelling of Elastomer FrictionFunding source: E.P.S.R.C.Start: 01-10-2013 / End: 31-03-2017 This EPSRC Case award examined how surface roughness effected the sliding friction for a wide range of different elastomer and rigid surface interactions. |

Electrical Breakdown of Dielectric ElastomersFunding source: NPL Management LtdStart: 01-10-2012 / End: 30-09-2016 Dielectric elastomers actuators are being developed to achieve large strains, requiring high electric fields approaching the dielectric breakdown strength of the material. The mechanisms that lead to breakdown in these materials was investigated. |

Dielectric Elastomer Actuator DevicesFunding source: ARTISStart: 01-10-2012 / End: 30-09-2016 This project developed new materials and applications for dielectric polymer composite structures which are “smart” materials. The development of new materials with an increased response to an applied voltage will allow new applications to be developed. |

Abrasion of Elastomer MaterialsFunding source: Cabot CorporationStart: 01-11-2013 / End: 30-04-2016 Abrasion tests were coupled to finite element fracture mechanics. The project demonstrated that the rate of abrasion under a wide range of friction conditions could be predicted from measurements made on independent fatigue test pieces. |

Dynamic Behaviour of Filled ElastomersFunding source: Sibelco UK Ltd & EPSRC Case AwardStart: 01-10-2010 / End: 31-03-2014 This project is examined how the visco-elastic properties of different filled elastomer materials were affected by compounding and test temperature. The aim was to deduce the fundamental reinforcing mechanisms of filled elastomer materials. |

Fatigue Failure in Aircraft TyresFunding source: Dunlop Aircraft Tyres Ltd & EPSRC Case AwardStart: 22-03-2010 / End: 21-03-2013 This project extended fatigue crack growth evaluated using simple test pieces to predicting the fatigue failure of real components. Finite element techniques were applied to calculate the tearing energy relationships with an emphasis on inter layer fatigue peeling failure in aircraft tyres. |

Other Research Projects

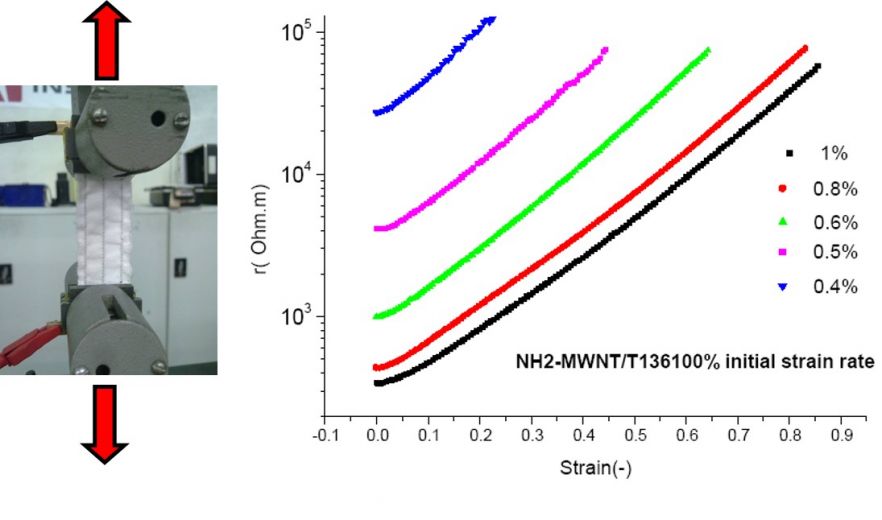

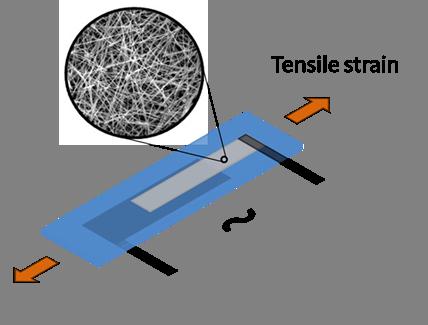

Smart Rubber Sensor DevicesThis work investigates how changes in the DC electrical properties (resistivity) change with strain for elastomers filled with conducting fillers such as carbon black. Broadband dielectric spectroscopy is used to measure the behaviour to see if more robust sensor type materials can be developed. |

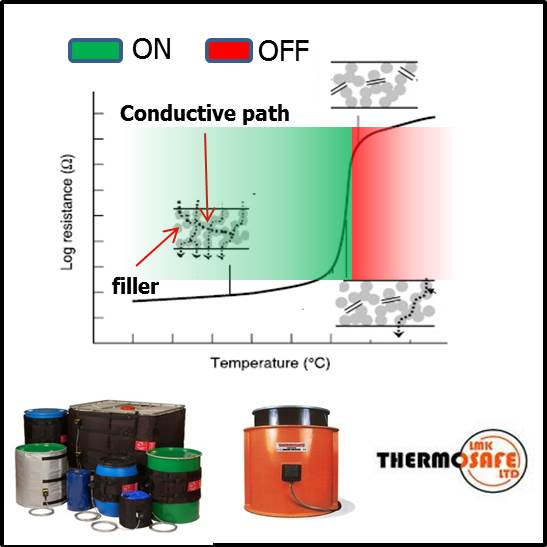

Self-regulating Heating MaterialsThe dramatic increase in electrical resistance with temperature (pyro-resistive or PTC effect) is in development in self regulating heating devices. Various projects in collaboration with LMK Thermosafe have developed next generation compounds that outperformed previous commercial materials. |

Optimisation of a Polymeric Heart ValveProsthetic heart valves must be both durable and bio-compatible. The Structured Materials group at Cambridge University has developed an injection moulded polymeric heart valve whose fatigue performance is being evaluated. Prototypes must exceed a billion cycles in accelerated fatigue tests, to ensure a reliable lifetime prediction in service. |

Haptic and Optical Systems Controlled Using Dielectric Elastomer ActuatorsThis work investigates the potential of dielectric elastomer actuators for tuneable haptic and optical systems. Our efforts have focused on the development of tactile displays, tuneable windows and tuneable optical lenses, as highly innovative devices for biomedical and bioinspired mechatronic systems. |

Friction Behaviour of RubberThe project examines how friction behaviour depends upon elastomer compounding, surface roughness, sliding speed, temperature and surface preparation. The project uses a range of finite element analysis modelling techniques to observe how phemomenon such as Schallamach waves are formed during sliding. |

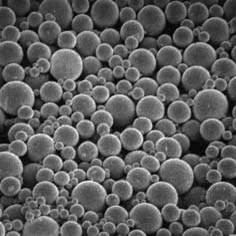

Foamed RubbersA hollow filler material can be used to create a closed cell foam structure. The full behaviour of this type of foamed elastomer is not well understood. The behaviour is observed in transparent elastomer materials using microscopy techniques to observe the process of bending, buckling and any dewetting at the rubber filler interface. |

Filler reinforcement in elastomersFunding source: Bridgestone / Cabot CorpMaterials such as carbon black, clays and silica significantly improve the mechanical properties measured in terms of strength and fatigue resistance when compounded into elastomers. This work uses different models over a wide range of length scales to understand polymer filler interactions at the atomic scale to micro-structural finite element models at the nanoscale. |

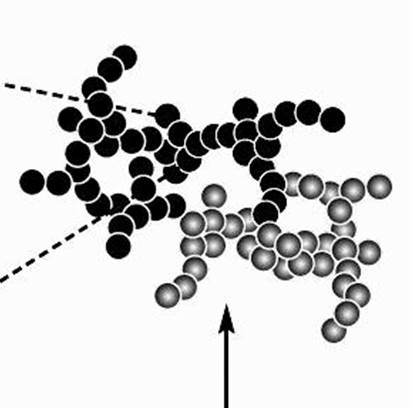

Dynamic simulation of flocculation: fractal particles in a polymer matrixThe structure of a colloidal dispersion depends sensitively on the amount of shear used during processing, on the shearing time, on the particle size, on the particle structure, and on the surface chemistry of the particles. In this project, we will explore these parameters numerically, with the specific goal of understanding filler dispersion in rubber composites. |

Business of Fashion, Textiles and Technology (BFTT), developing more Sustainable, Circular and Intelligent Wearables for the Fashion and Textile Industry.Delivering sustainable innovation within the entire fashion and textile supply chain. |