Research

Carbon Nanotube - Polymer Composites

| Principal investigator: | |

| Co-investigator(s): |

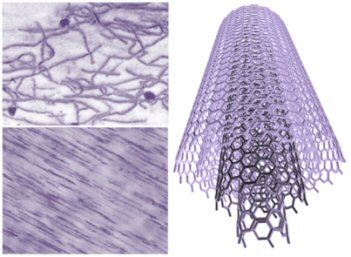

Among the wide range of available nanofillers, carbon nanotubes (CNTs) have attracted particularly interest as reinforcing fillers because of their superb mechanical properties (Young’s modulus 1 TPa and tensile strength 30-130 GPa), but they are also regarded as the ultimate fillers for creating electrically conductive polymer composites (CPCs). Despite their amazing promises in mechanical properties, the success of carbon nanotubes as reinforcements for polymer composites has been limited and not yet led to a wide range of commercial products, one reason being the difficulty in dispersing them in the hosting matrix. This is not a trivial task, since the extremely large surface area that characterizes nanotubes is responsible for their strong tendency to form agglomerates. In addition, good interfacial interaction and stress transfer between carbon nanotubes and polymer matrices is essential for good mechanical properties of the composites. Finally, similar to macromolecules, the excellent intrinsic mechanical properties of CNTs can only be completely exploited if uniaxial orientation is achieved.

Among the wide range of available nanofillers, carbon nanotubes (CNTs) have attracted particularly interest as reinforcing fillers because of their superb mechanical properties (Young’s modulus 1 TPa and tensile strength 30-130 GPa), but they are also regarded as the ultimate fillers for creating electrically conductive polymer composites (CPCs). Despite their amazing promises in mechanical properties, the success of carbon nanotubes as reinforcements for polymer composites has been limited and not yet led to a wide range of commercial products, one reason being the difficulty in dispersing them in the hosting matrix. This is not a trivial task, since the extremely large surface area that characterizes nanotubes is responsible for their strong tendency to form agglomerates. In addition, good interfacial interaction and stress transfer between carbon nanotubes and polymer matrices is essential for good mechanical properties of the composites. Finally, similar to macromolecules, the excellent intrinsic mechanical properties of CNTs can only be completely exploited if uniaxial orientation is achieved.

Our research has been exploring the potential of CNTs as reinforcements for polymer composites, with a particular emphasis to oriented systems like tapes and fibres. In addition, the use of CNTs as conducting filler has been investigated, with special attention to the application as sensor materials. The reinforcement potential of single-walled nanotubes (SWNTs) as well as multi-walled nanotubes (MWNTs) in a variety of polymers has been studied incl. UHMW-PE, PP, PA, PC, PVA and epoxy to name a few. A wide range of processing methods are used incl. solution-based routes, melt-blending and supercritical CO2 processing. The group has reported one of the highest reinforcing efficiencies for nanotubes for a PVA based system using dimethyl sulfoxide (DMSO) as a solvent. Micromechanical analysis showed that for these PVA/SWNT composites the nanotube contribution to the composite strength was as high as 80 GPa, approaching theoretical strength limits. Besides their use as mechanical reinforcements a significant research effort of the group is also in the use of CNTs as flame retardants for polymers, often in combination with other nanofillers such as nanoclays. The group works in close collaboration with Nanocyl S.A. in Belgium, a global leader in nanotube production.