Research

Efficient Numerical Modelling of Moving Contact Lines under Non-isothermal Conditions

| Principal investigator: | Yi SUI |

| Funding source(s): | Commission of the European Community - 658437 |

| | Start: 17-08-2015 / End: 31-08-2018 |

| | Amount: £127,046 |

| Directly incurred staff: | Dr Yongpan Cheng |

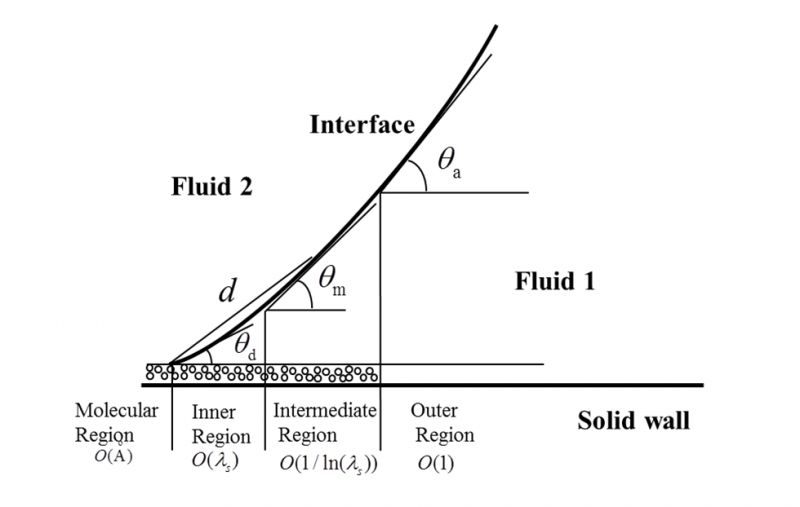

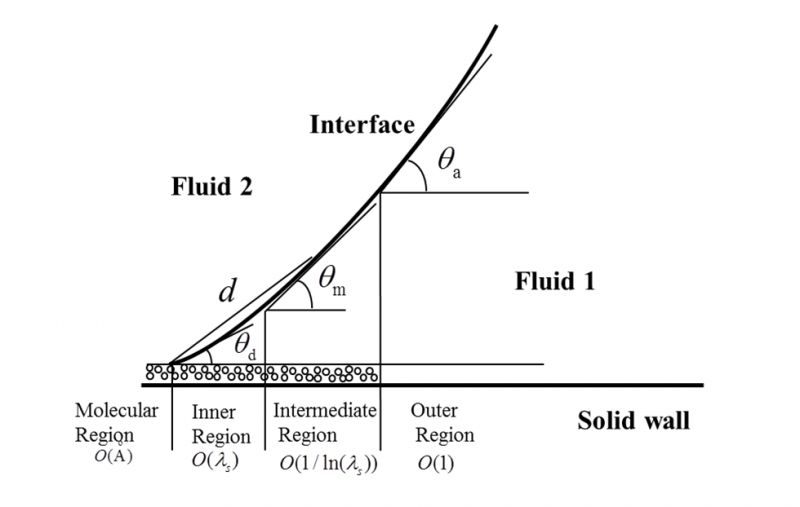

Flows with moving contact lines (MCLs) are the heart of numerous industrial applications, such as surface coating, mould filling, displacement of oil by CO2, spray cooling, condensing, microreactors etc. Although moving contact line is only a small part of the flow even in small systems, in fact the speed of the contact line and the dynamic contact angle largely control the flow. Improved understanding of MCL dynamics and capability of predictive analysis of flows involving MCLs will therefore greatly benefit the design and optimization of numerous industrial applications. In many practical systems, contact lines move under non-isothermal conditions, for example, in fire flooding, in condensers, in droplet impact on a hot substrate in spray cooling, etc. Despite considerable attention and decades of development, the understanding for dynamics of moving contact lines is still far from enough. In this project, we aim to develop a non-isothermal combined theory for MCL dynamics and then use it to build a novel macroscale computational model, which can simulate non-isothermal MCL flows efficiently and accurately. The specific research objectives are:

Flows with moving contact lines (MCLs) are the heart of numerous industrial applications, such as surface coating, mould filling, displacement of oil by CO2, spray cooling, condensing, microreactors etc. Although moving contact line is only a small part of the flow even in small systems, in fact the speed of the contact line and the dynamic contact angle largely control the flow. Improved understanding of MCL dynamics and capability of predictive analysis of flows involving MCLs will therefore greatly benefit the design and optimization of numerous industrial applications. In many practical systems, contact lines move under non-isothermal conditions, for example, in fire flooding, in condensers, in droplet impact on a hot substrate in spray cooling, etc. Despite considerable attention and decades of development, the understanding for dynamics of moving contact lines is still far from enough. In this project, we aim to develop a non-isothermal combined theory for MCL dynamics and then use it to build a novel macroscale computational model, which can simulate non-isothermal MCL flows efficiently and accurately. The specific research objectives are:

(1) to investigate the dependency of the dynamic contact angle on the contact line speed and other system parameters using systematic experiments, and to develop fundamental understandings of the results

(2) to develop a non-isothermal theory to predict the interface shape close to the MCL

(3) to develop a novel macroscale computational model for efficient simulations of non-isothermal MCL flows and to validate the model